top of page

Production Investment Castings

Annual or repeat orders.

Exceptional ROI for your production or prototyping projects.

SOME OF THE BENEFITS INCLUDE:

Extreme freedom

At Invest Cast Inc, we know product design is ever-changing and always improving. That’s why we allow you extreme freedom in part design. Your vision and our flexibility ensure that your ideas become reality – with speed and precision.

Wide Selection of Alloys

Our wide array of castings are currently poured in alloy steel, tool steel, stainless steel, cobalt base, nickel base, copper base and aluminum base.

Excellent Surface Finish

Production – 125 RMS or Better

Prototype – 175 RMS is typical

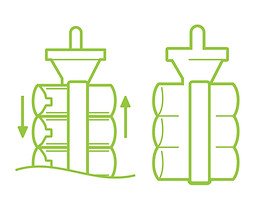

Economical Low and High Volume Process

Low volume production can be accomplished with relatively simple, single cavity tools while high volume production requirements can be met with fully automated multiple cavity molds.

Close Tolerances

Standard tolerances are ±.005″ per inch, 1/2 of Standard is possible.

Thin Walls

Wall thickness can be cast as thin as .025″, depending on alloy and part configuration.

HOW IT WORKS

Production Casting Process

Wax Injection

The first step in the investment casting process is to produce a wax replica of the desired part. This is accomplished by injecting wax into a die cavity.

Pattern Removal

After injection, the wax replica is removed from the injection tool. Parts are inspected for tolerance and then cleaned for assembly.

Wax Assembly

Patterns are “wax welded” to a central sprue or cluster to facilitate pouring. Many patterns are attached to sprues for increased efficiency

Shell Building

The assembled sprue is then dipped into a ceramic slurry. After draining, the sprue is then coated with a fine silica or stucco sand. This process is repeated several times using progressively coarser grades of ceramic material to build sufficient “shell” strength.

De-waxing

The shell built sprue is then de-waxed by rapidly heating in a furnace or autoclave, leaving behind the perfect shell cavity free of wax.

Preheating shell

The shells are then fired at 1600° to 2000°. This cures the shells interior into a smooth, hard and strong ceramic material.

Pouring

The sprues are then removed from the furnace to have the molten metal poured into them. Once the shell is filled with metal, it needs to cool and have the shell material removed from the outside of the casted parts.

Part Finishing

Once clear of ceramic shell, the cast parts get cut off from the sprue, then they are brought through a number of finishing processes. These processes include various cleaning stages, grinding, plating, machining, and heat treat.

bottom of page